- ELIVATOR

- HAMMER MILL FULL SCREEN

- HAMMER MILL HALF SCREEN

- MIXER

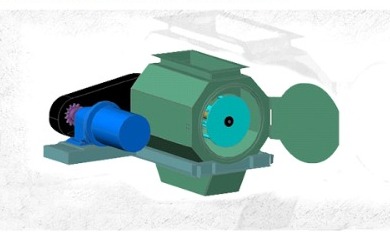

- PELLET MILL HORIZONTAL

- PELLET MILL VERTICAL

- COOLER

- CRUMBLER

- SEIVE MACHINE

- JUTE REMOVER

- INSTALLATION

- COMMISSION

Jute Remover Machine

Before processing of ingredients, it is essential to remove oversize, foreign materials and iron impurities etc. which otherwise can affect functioning of slide gates, gravity / screw feeders in batching or down stream. Pre Cleaning machines generally include rotary sieve, jute remover, magnetic catchers etc. In automatic plants, it is desired that system is designed to give continuous efficient cleaning at maximum flow ingredients.

Bag Emptying Station

The dirty or tainted air enters the dust collector through the module inlet and goes through various channel cartridges, which retain the dust particles on the outside surface while permitting clean air to pass through the module outlet.

As the collector works, the collected dust starts to form a dust cake, which eventually diminishes the porosity of the filter cartridges. As the pressure drop builds the ventilation volume of the collection decreases.

To keep up a moderate pressure drop, the cleaning cycle is utilized to give continuous cleaning of the filter cartridges. The cleaning system consists of a strong state programmable timer, which actuates electric solenoids governing the air valves. These air valves deliver flashing burst or beat of high compacted air through the complex funnel into the filter tube. This push of air makes the reverse flow of air, which grows the filter cartridges to remove the collected dust.

The cleaning methodology happens to a row-by-row basis, therefore only a fraction of total filtered air is interrupted for cleaning permitting consistent ventilation.

The dust cake pulsed beat from the filter cartridges falls straightforwardly into the bucket at the base where it is removed.

An exhaust fan suitable for air volume 1000 cubic feet for each moment and is mounted on the highest point of dust collector, which creates the negative draft throughout the procedure.

Magnet Cleaning System

Different magnetic devices are used for separation of iron particles from material being processed. These include rotary magnets, magnetic grill, cascading magnets etc.

Our cascading magnets are designed to catch iron impurities from very small particles of iron dust to big pieces with equal ease with almost 100% efficiency at maximum designed flow rate of plant. This is achieved by using high power rare earth magnets enclosed in stainless steel housing.

The magnets are of self cleaning design means you don’t have to remove the iron impurities from magnets by hand. It is now simplified with just unclamping the magnetic plate without using any tools and with just a pull of handle, all the entrapped metal falls in collection tray. Collection tray is detachable for cleaning.

Heavy Duty

This Elivator Machine is a heavy duty single leg machine

with Capacity of 8 Mt/Hr. (Model JST200)

High Performance

This is a high performance machine with features of Box Fabrication

Top and Bottom of elevator fabricated with 4mm, Boxes.

Quality Assaurations

We Manufectures this machine under the highest quality standards

of the industry.

.jpg)