- ELIVATOR

- HAMMER MILL FULL SCREEN

- HAMMER MILL HALF SCREEN

- MIXER

- PELLET MILL HORIZONTAL

- PELLET MILL VERTICAL

- COOLER

- CRUMBLER

- SEIVE MACHINE

- JUTE REMOVER

- INSTALLATION

- COMMISSION

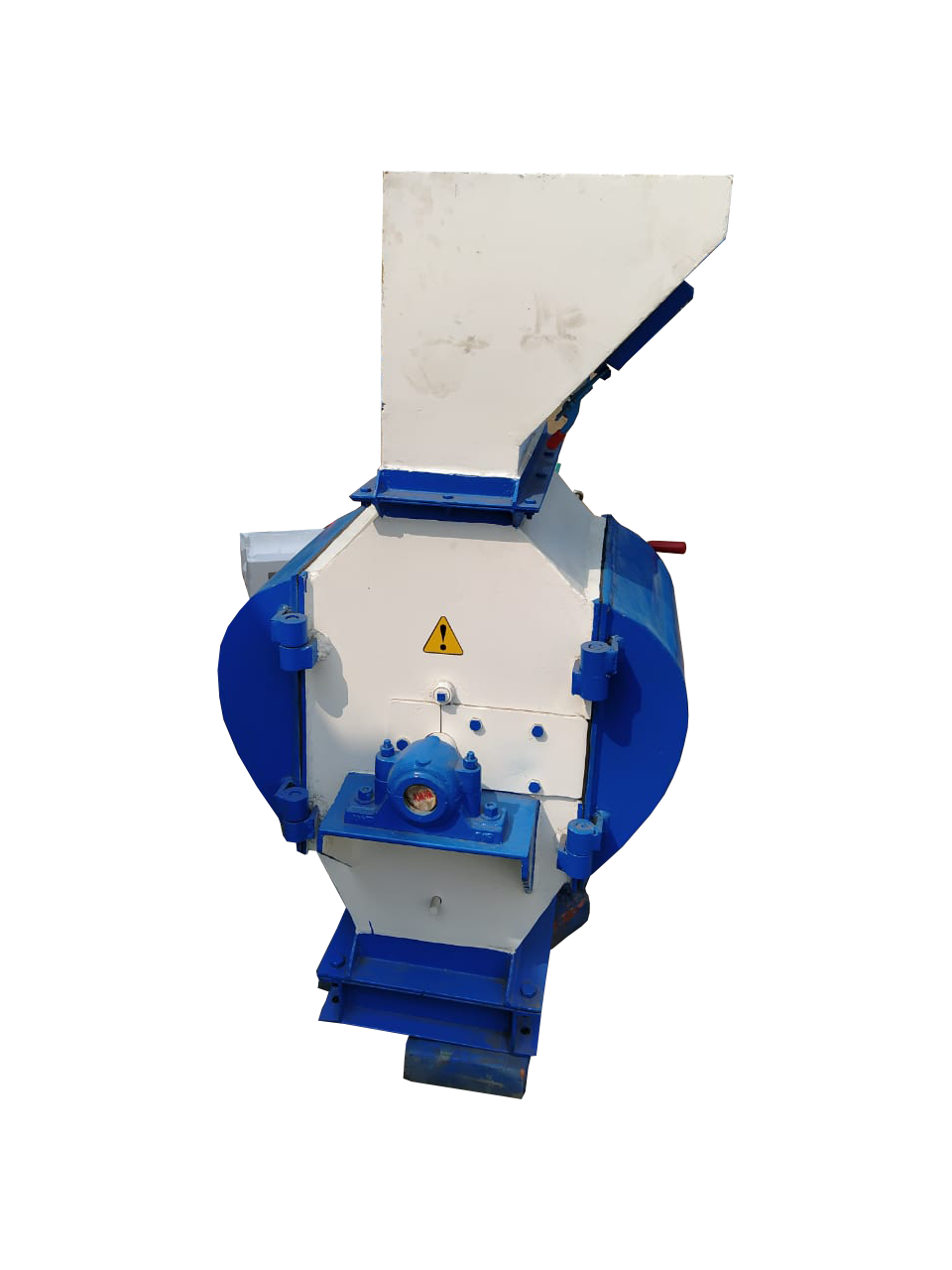

Full Screen Hammer Mill

In industry where we need to reduce the particle size of a product so as to use it effectively, we use different machines to solve the purpose which include hammer mills, grinders, roller mills etc. In hammer mills impact force of high-speed rotating hammer is utilized to crush a material. Though our Hammer mills are being used in many industries with different design features, here we will discuss regarding hammer mills being used in animal feed industry.

Animal feed consists of different ingredients to make a balanced diet in terms of proteins, carbohydrates, fats, vitamins, minerals and medicines etc. There are few ingredients which are already available in powder form while the others like grains and cakes (by products of oil extraction plants from soya, groundnuts, mustard etc) need to be reduced to the required particle size to help to achieve to following:

Expose greater surface area for digesting.

Improve mixing characteristic of ingredients.

Improve ease of handling of some ingredients

Basic Hammer Mill Design

A typical hammer mill consists of a horizontal rotor assembly fitted inside a metal housing. The rotor assembly includes a shaft and several circular plates mounted on it with equal spaces between plates. Plates are having holes on its outer PCD to accommodate hammer pins on which swinging hammers are fitted. A perforated metal screen is forming either a full circle or half circle fits around the rotor assembly. The diameter of hole in screen is selected to match the desired particle size.

A material inlet is typically located at the housing top and a material outlet is located below the housing. A flow deflector is mounted below the material inlet to deflect the material either way to assist grinding.

The Grinding Theory

The product enters from the top of hammer mill, fall at a moving speed of 30 to 60 ft per minute. The product comes in contact with very

high-speed moving hammers at the top of their swing. The entering product can be assumed almost stationery as compare to very high tip speed of hammers. Due to huge difference in relative speed of each other, when contact is made, due to high impact force product is shattered in particles.

After this action, hammers begin to pull material into acceleration zone where the particles will increase in velocity to attain hammer tip speed. As soon as the particles attain the exit velocity, they are thrown out of grinding chamber.

Hammer Mill Manufacturer in Bihar | Hammer Mill Manufacturer in Uttar Pradesh | Hammer Mill Manufacturer in Assam | Hammer Mill Manufacturer in Jharkhand | Hammer Mill Manufacturer in Madhya Pradesh | Hammer Mill Manufacturer in Rajasthan | Hammer Mill Manufacturer in Tripura | Hammer Mill Manufacturer in Maharashtra | Hammer Mill Manufacturer in Gujarat | Hammer Mill Manufacturer in Jammu Kashmir | Hammer Mill Manufacturer in Andhra Pradesh | Hammer Mill Manufacturer in Tamil Nadu | Hammer Mill Manufacturer in West Bengal | Hammer Mill Manufacturer in Nepal | Hammer Mill Manufacturer in Bangladesh | Hammer Mill Dealer in Bihar | Hammer Mill Dealer in Uttar Pradesh | Hammer Mill Dealer in Assam | Hammer Mill Dealer in Jharkhand | Hammer Mill Dealer in Madhya Pradesh | Hammer Mill Dealer in Rajasthan | Hammer Mill Dealer in Tripura | Hammer Mill Dealer in Maharashtra | Hammer Mill Dealer in Gujarat | Hammer Mill Dealer in Jammu Kashmir | Hammer Mill Dealer in Andhra Pradesh | Hammer Mill Dealer in Tamil Nadu | Hammer Mill Dealer in West Bengal | Hammer Mill Dealer in Nepal | Hammer Mill Dealer in Bangladesh | Hammer Mill Supplier in Assam | Hammer Mill Supplier in Jharkhand | Hammer Mill Supplier in Madhya Pradesh | Hammer Mill Supplier in Rajasthan | Hammer Mill Supplier in Tripura | Hammer Mill Supplier in Maharashtra | Hammer Mill Supplier in Gujarat | Hammer Mill Supplier in Jammu Kashmir | Hammer Mill Supplier in Andhra Pradesh | Hammer Mill Supplier in Tamil Nadu | Hammer Mill Supplier in West Bengal | Hammer Mill Export in Nepal | Hammer Mill Export in Bangladesh

Heavy Duty

This Elivator Machine is a heavy duty single leg machine

with Capacity of 8 Mt/Hr. (Model JST200)

High Performance

This is a high performance machine with features of Box Fabrication

Top and Bottom of elevator fabricated with 4mm, Boxes.

Quality Assaurations

We Manufectures this machine under the highest quality standards

of the industry.

.jpg)